Have you ever needed to get something fixed quickly, but didn’t have the time or money to find a permanent solution? A hot glue gun is your savior! You may not be aware of it, but this handy tool has been used by people for decades and never ceases to surprise us with its power. But who invented such a revolutionary device? In this article, we’ll take an in-depth look at the history of the hot glue gun – from its conception to present-day use. Join us on our journey as we discover all about how this incredible advancement came into being

Table of Contents

The Evolution of the Glue Gun

The invention of the hot glue gun is credited to George Schultz, a simple man with a vision for convenience and efficiency. Born from the need for a powerful adhesive that could be rapidly deployed and dried, the hot glue gun has carved its niche across various industries and households. Since its inception in the 1954, the hot glue gun has seen numerous transformations, each improving upon its design, functionality, and user-friendliness. [1] Let’s delve deeper into the journey of this humble tool, a journey marked by innovation, evolution, and a persistent commitment to making lives easier.

Paul Cope

As we progress through the chronicles of the hot glue gun, an important figure enters the scene – Paul W. Cope. Cope, an inventive mind from the mid-20th century, is often credited with the creation of the thermoplastic adhesive, a key component that revolutionized the utility of the hot glue gun. Before this innovation, most adhesives required a longer curing period, delaying the bonding process. However, Cope’s thermoplastic adhesive introduced an adhesive that rapidly solidifies upon cooling, dramatically reducing the waiting time.

This invention was a game-changer, bringing an unparalleled level of convenience and speed to both industrial and household applications. From packaging industries to art and craft hobbies, the thermoplastic adhesive, coupled with the efficiency of the hot glue gun, made an indelible impact. It’s safe to say that without Cope’s contribution, the hot glue gun as we know it today wouldn’t exist. To this day, Cope’s invention continues to glue the world together, one hot melt stick at a time.

George Schultz’s Polygun

Building on the foundation laid by previous inventors, George Schultz introduced the world to the Polygun in the 1954, which quickly became a staple in many industries and households. The Polygun was a hot glue gun that utilized thermoplastic adhesive in stick form, further enhancing the efficiency and convenience of the tool.

With a heating element designed to quickly and safely melt the glue stick, the Polygun offered a simplified, clean, and rapid adhesive application process. The device itself was lightweight, easy to handle, and safe for use, even by individuals with no prior experience. It represented a leap in the evolution of the hot glue gun, bringing about a new era of quick fixes and creative possibilities.

Early impacts on glue gun design

The design influences behind early glue guns are an intriguing blend of pragmatism, simplicity, and ingenuity. From its inception, the hot glue gun was intended to be a tool that anyone could use with ease, whether they were an experienced craftsman, an artist, or a hobbyist. This was reflected in its lightweight form factor, easy handling, and simple operation mechanism. The initial design was largely utilitarian – a heating element, a trigger mechanism, and a slot for inserting the glue stick.

As the glue gun evolved, however, the design became more sophisticated, incorporating features to enhance usability and safety. Plastic and rubber materials were introduced to make the gun lightweight and insulate the user from the heat. Innovations like stand-alone bases and precision nozzles were incorporated for improved stability and accuracy. Despite these advancements, the essence of the glue gun’s design remained unchanged—it continued to be a tool that was easy to use, reliable, and extremely versatile.

Carl Weller

Another key figure in the development of the hot glue gun is Carl Weller. Weller, an accomplished inventor, and engineer, is largely known for his contributions to soldering technology. However, his innovations also had a profound influence on the design and functionality of the hot glue gun. In 1941, Weller patented a soldering gun that used a transformer to convert household electricity into the low-voltage, high-amperage current required for soldering. This technology, while initially used for soldering, soon found its way into hot glue guns. [2]

By applying the principles of Weller’s soldering gun to the hot glue gun, manufacturers were able to create a device that was not only portable but also able to heat up quickly and maintain a consistent operating temperature. This allowed for a more efficient melting of the glue stick and a more controlled application of the adhesive. Without Weller’s pioneering work, the hot glue gun may not have evolved into the versatile and user-friendly tool we know today.

The Nordson AD-25

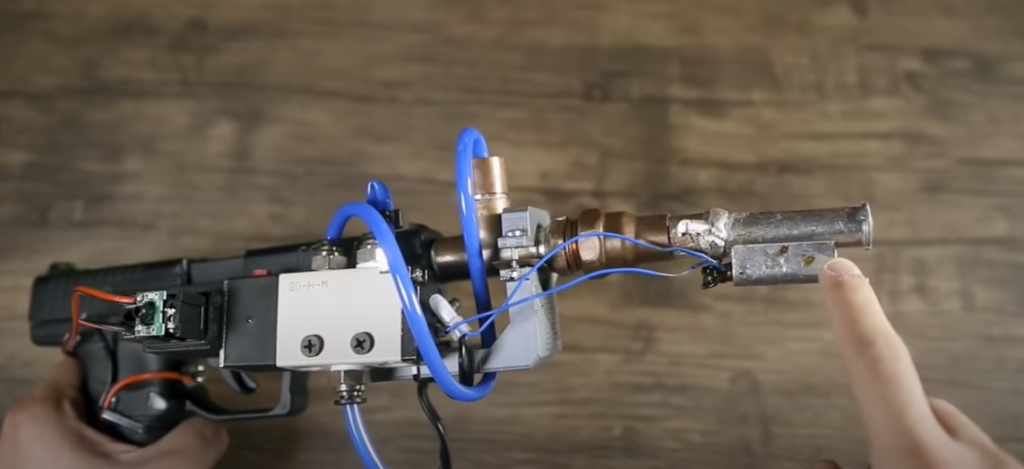

The Nordson AD-25, launched in the early 1973, represents a significant milestone in the evolution of the hot glue gun. The Nordson Corporation, a global leader in precision dispensing equipment, took the concept of the hot glue gun and enhanced it further. [3] The AD-25 was a pneumatic glue gun designed for industrial use, able to deliver precise amounts of hot melt adhesive quickly and consistently.

Unlike previous glue guns, the AD-25 used a tank to store and heat a larger volume of adhesive, rather than relying on individual glue sticks. This allowed for continuous operation over longer periods, making it ideal for assembly line work in industries such as packaging, electronics, and automotive. The AD-25 also featured an adjustable temperature control system, offering greater flexibility in the use of different types of adhesives.

Moreover, it incorporated a pneumatic system to push the molten adhesive through the nozzle, providing better control and precision in adhesive application. The Nordson AD-25 was a testament to the potential of the hot glue gun, demonstrating its capacity not just as a helpful tool for quick fixes and craft projects, but also as an indispensable piece of equipment for modern industry.

The glue gun revolution

The glue gun revolution was marked by rapid advancements, both in terms of design and functionality. The rise of cordless technology was a game-changer, leading to the development of battery-operated glue guns that offered greater portability and flexibility. Mini glue guns also gained popularity during this period, proving ideal for intricate crafting work and small-scale repairs. The evolution of adhesive technology also played a key role in shaping the advancements in glue gun technology.

Different types of glue sticks were introduced to cater to a variety of applications – colored sticks for craftwork, high-strength adhesives for heavy-duty tasks, and temperature-specific glue sticks for sensitive materials. As the digital age emerged, manufacturers began integrating microprocessors into glue guns to offer precision temperature control and automatic switch-off features, further enhancing safety and efficiency. The emphasis on user convenience and comfort also led to ergonomic improvements in design, such as rubberized grips, stand assist, and anti-drip features.

Robert L Ornsteen

In the realm of glue gun innovation, Robert L. Ornsteen’s design for a 43mm glue gun stands out as a significant breakthrough. Ornsteen, an industry veteran, developed a glue gun that was specifically designed to accommodate 43mm glue sticks, larger than the standard size used by most models at the time. This innovation was guided by a simple but powerful concept: by increasing the size of the glue stick, one could extend the operating time of the glue gun, thereby improving its efficiency and ease of use.

The 43mm glue gun incorporated several design features to accommodate its larger glue stick size. Firstly, the heating chamber was designed to have a larger diameter, ensuring that the 43mm glue stick could fit securely and melt evenly. The trigger mechanism was also re-engineered to deliver a higher force, which was necessary to dispense the larger volume of adhesive. Despite these modifications, Ornsteen’s design maintained a compact and ergonomic form factor, ensuring that it remained user-friendly and comfortable to use over extended periods.

The Plastitherm PG 751

In the year 1979, the Plastitherm PG 751 made its debut, heralding a new era for hot glue guns. Manufactured by the renowned Italian company Plastitherm, the PG 751 offered a number of novel features that distinguished it from its predecessors. Its most notable innovation was the use of ceramic heating elements, which offered superior thermal efficiency and a faster heat-up time compared to traditional metal-based heating elements. [4] Additionally, the gun was capable of reaching a maximum temperature of 220 degrees Celsius, making it suitable for use with a wide range of adhesive types.

The glue gun also showcased a digital temperature control system, allowing users to fine-tune the operating temperature according to their specific requirements. The PG 751 also boasted an advanced safety feature – an automatic shut-off system that deactivated the heating element after a specified period of inactivity, thus preventing overheating and potential accidents.

The TEC power adhesives

Another significant player in the glue gun industry is the UK-based company TEC Power Adhesives. Known for its innovative designs and high-performance products, TEC Power Adhesives has made a substantial impact on the industry with its range of hot glue guns. One of their most notable models is the TEC 810, a 12mm glue gun that balances power, precision, and ease of use. The TEC 810 boasts a robust and durable design, making it suitable for both industrial and DIY applications. A standout feature of this model is its adjustable temperature control, which allows users to select the optimal temperature for the glue they are using. This feature, coupled with a fast heating time and a high melt rate, ensures efficient performance in a variety of tasks.

Another key feature of the TEC 810 is its ergonomic design, which includes a comfortable grip and an easy-to-use trigger, reducing user fatigue during prolonged use. In keeping with the company’s emphasis on safety, the TEC 810 also includes an auto shut-off feature that powers down the glue gun after 30 minutes of inactivity, helping to prevent accidental burns and fires.

The Modern Glue Gun

Today’s glue guns are marvels of design and technology, enabling users to undertake a wide range of tasks with precision, efficiency, and safety. Modern glue guns come with features such as rapid heat-up times, adjustable temperature settings, and auto shut-off systems for enhanced safety. They are designed to accommodate varying sizes of glue sticks, from mini glue sticks for delicate work to larger ones for industrial applications. The heating elements have also seen significant advancements, with ceramic elements offering superior thermal efficiency and consistency over traditional metal-based elements. There’s a continued emphasis on ergonomics, with manufacturers designing glue guns that are comfortable to hold and operate over extended periods.

Some models even feature integrated LED lights for improved visibility and precision in low-light conditions. The increasing use of digital controls in glue guns allows users to adjust temperature settings with precision, ensuring optimal performance across a variety of tasks and adhesive types. This constant evolution and improvement of glue gun technology inspire confidence in its future, with endless possibilities for innovation and enhancement continuing to unfold.

What is glue made of?

Glue, also known as adhesive, is a substance used to bond two or more objects together. The primary components of glue vary widely depending on its type and purpose. The most common types include PVA (Polyvinyl Acetate), Epoxy, Cyanoacrylate, and Animal Glue.

PVA glue, often used in crafting and woodwork, is a synthetic polymer that is water-soluble. Epoxy glues are a class of reactive polymers and prepolymers that form strong bonds and are resistant to high temperatures and chemicals. They consist of two parts: a hardener and a resin, which must be mixed together before use. Cyanoacrylate, also known as super glue, is a fast-acting adhesive that forms a strong bond almost instantly upon exposure to air. Animal glue, as the name suggests, is made by boiling animal tissue and bones, and while less common today, it is still used in certain specialty applications such as bookbinding and furniture restoration. [5]

Each type of glue has a unique set of properties and is designed for specific uses, from everyday household tasks to complex industrial applications. The composition of glue plays a significant role in determining its adhesive strength, drying time, flexibility, and resistance to heat, chemicals, and moisture.

How does a glue gun work?

A glue gun works on the principle of heating to melt the glue stick and then uses a trigger mechanism to dispense the molten adhesive. When the glue stick is inserted into the back of the glue gun, it comes into contact with a heating element. This heating element, often a ceramic PTC (Positive Temperature Coefficient) heater, heats up quickly and melts the glue stick, transforming it from a solid to a liquid state. The PTC heater’s self-regulating property ensures that the glue gun does not overheat, maintaining a consistent optimal temperature for melting the glue.

The melted glue is then ready to be dispensed. When the user pulls the gun’s trigger, it pushes the glue stick further into the heating element, forcing the melted glue out of the gun’s nozzle. The amount of glue dispensed can be controlled by the pressure applied to the trigger. Once the trigger is released, a check valve near the nozzle closes, preventing the backflow of glue and ensuring precise application.

The molten glue cools and solidifies quickly once dispensed, creating a strong bond between the surfaces to which it is applied. This is due to the rapid loss of heat to the surrounding environment and the surfaces being bonded, causing the polymer chains in the glue to contract and harden. The glue gun’s design allows for quick, easy, and controlled application of adhesive, making it a versatile tool for a wide range of tasks. From craft projects and home repairs to industrial applications, the glue gun’s efficiency and ease of use make it an indispensable tool in various fields.

Ways to use Hot Glue Gun

Hot glue guns boast an impressive range of applications, spanning different fields and industries. In the realm of arts and crafts, they are used extensively for assembling various materials, be it paper, fabric, or plastic, offering a secure and quick-drying adhesive solution. They also serve as a valuable tool in home repairs, helping fix broken furniture, sealing leaks, or even affixing loose tiles. Similarly, in the world of floral arrangements, hot glue guns aid in creating long-lasting, beautiful displays.

In the automotive industry, they are used for minor repairs and part installations. Fashion and jewelry designers use hot glue for attaching embellishments and creating intricate designs. Furthermore, in the realm of electronics, hot glue guns provide an efficient way to insulate wires and secure components in place. Thus, the hot glue gun, with its broad spectrum of applications, underscores its undeniable versatility and indispensability.

Frequently Asked Questions

Why are glue guns so hot?

Glue guns get hot because they contain a heating element that melts the glue stick inside them. This heating component is typically a ceramic PTC (Positive Temperature Coefficient) heater, which heats up quickly, transforming the solid glue stick into a liquid state. This heat is essential for the glue gun to function properly, as it enables the adhesive to be easily dispensed and bond materials effectively. Once the melted glue is applied to a surface, it cools down rapidly, reverting to a solid state and creating a strong adhesive bond. The high temperature of the glue gun, which generally ranges from 250 to 380 degrees Fahrenheit (120 to 193 degrees Celsius), ensures optimal performance and effectiveness but also necessitates careful handling to prevent burns or injuries.

How old is the oldest glue?

The oldest known glue dates back approximately 200,000 years. Archaeologists discovered evidence of its use by Neanderthals in the form of birch bark tar in Italy. However, the first confirmed use of glue for binding purposes was found in paintings in the Lascaux and Altamira caves, dating back around 15,000 to 20,000 years. The adhesive used was likely a form of natural glue made from tree sap or tar.

Who invented glue sticks?

The glue stick was invented by the German company, Henkel, under the brand name Pritt Stick. The idea was conceptualized by Dr. Wolfgang Dierichs, who was the company’s researcher. During a trip to the United States, he noticed children applying glue using lipstick applicators. This observation inspired him to develop a similar, non-toxic adhesive tool for use in schools and offices. The first Pritt Stick was launched in 1969 and quickly gained popularity for its convenience, cleanliness, and non-toxicity, revolutionizing the way adhesive was applied in schools, homes, and workplaces.

How hot is a glue gun?

A glue gun generally operates at a temperature ranging from 250 to 380 degrees Fahrenheit, or 120 to 193 degrees Celsius. However, the exact temperature can vary based on the model and type of glue gun. There are low-temperature glue guns available which operate at around 250 degrees Fahrenheit, and high-temperature models which can reach up to 380 degrees Fahrenheit. The high temperature allows the glue stick to melt and be dispensed from the gun, and it solidifies quickly upon cooling, creating a strong adhesive bond. It’s always essential to handle glue guns with care to prevent potential burns or injuries.

Is the hot glue gun strong?

Yes, hot glue guns produce a strong bond. The glue dispensed from a hot glue gun cools and solidifies quickly, forming a robust adhesive bond that is quite durable. This strong bond makes hot glue guns suitable for a wide range of applications, from crafts and home repairs to industrial purposes. However, it’s essential to note that while hot glue is strong, it may not be the best choice for all materials or conditions. For instance, it might not hold up well under extreme temperatures or on surfaces that are frequently subjected to heavy stress or moisture.

Useful Video: Hot glue gun 3.0 – Super Soaker!

Conclusion

In summary, hot glue guns are an incredibly versatile tool used across various industries and applications. Their quick and efficient adhesive properties make them ideal for a vast array of tasks, from arts and crafts to home repairs and industrial purposes. However, their high operating temperature calls for caution while in use. The fascinating history of adhesives, dating back to prehistoric times, highlights the continuous human innovation in this field, culminating in practical tools like the glue gun and the glue stick. Despite the strength and versatility of hot glue, it’s crucial to choose the appropriate adhesive for specific tasks and conditions for optimal results.

References:

- https://www.hotmelt.com/blogs/blog/the-evolution-of-the-glue-gun

- https://en.wikipedia.org/wiki/Soldering_gun

- https://www.gluegunsdirect.com/service-and-advice/history-development-glue-gun/

- https://www.gluegunsdirect.com/2019/08/anyone-remember-the-plastitherm-pg-751-glue-gun/

- https://www.sciencedirect.com/topics/engineering/animal-glue

Leave a Reply